Geared Coupling

Geared Coupling

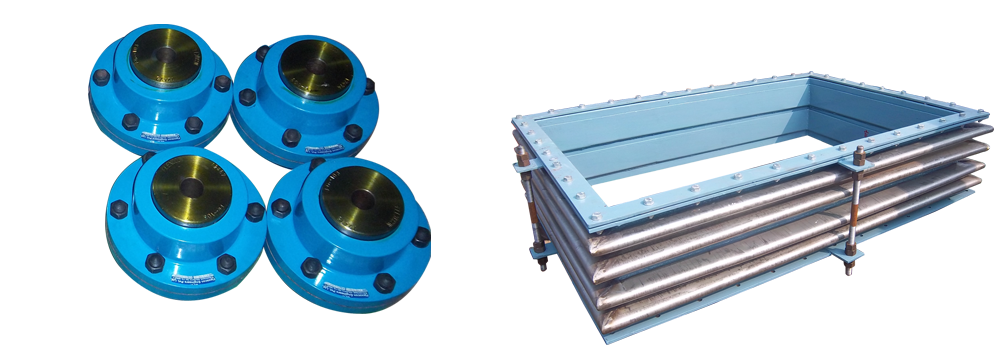

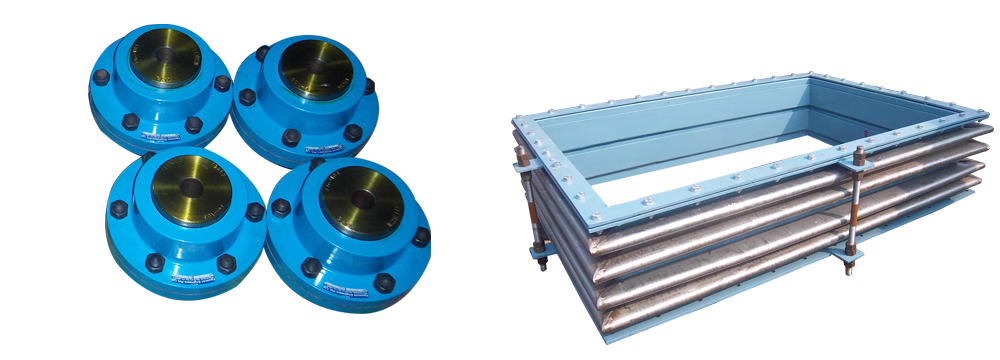

Flexocon Geared Couplings is used to join two rotating shafts for efficient transmission of Mechanical Power. Flexocon full gear Flexible Gear Coupling consists of two identical toothed hubs, two identical flanged sleeves with internal teeth, a gasket, a set of bolts, nuts and spring washers, lube plugs and two oil/grease retaining O-ring over the hubs. Flexocon Geared Couplings are manufactured employing tested raw materials through precision manufacturing processes using special purpose machines, jigs, fixtures, tooling and gauges and are subject to continuous inspection.

Flexocon Geared Couplings are designed and manufactured to accommodate Angular, Parallel and Axial Misalignments. Upto Plus/Minus 1.5 Degree angular misalignment capacity is provided in standard Couplings.

Features

Features

High Power to weight ratio.

High Power to weight ratio. Compact assembly.

Compact assembly. Accommodates angular, parallel and axial misalignment.

Accommodates angular, parallel and axial misalignment. Larger bore capacities.

Larger bore capacities. Crown Gear teeth for longer life.

Crown Gear teeth for longer life. Less backlash error.

Less backlash error. Heat treated as per application.

Heat treated as per application. Generally used upto 120°C.

Generally used upto 120°C. Close tolerance connecting bolts.

Close tolerance connecting bolts. Interchangeability.

Interchangeability. Range of Resilient Couplings

Range of Resilient Couplings

Full Geared Coupling.

Full Geared Coupling. Half Geared Half Rigid Coupling.

Half Geared Half Rigid Coupling. Mill Motor Type Coupling.

Mill Motor Type Coupling. BrakeDrum Type Geared Coupling.

BrakeDrum Type Geared Coupling. Spacer type Geared Coupling.

Spacer type Geared Coupling. Brake-disc Type Geared Coupling.

Brake-disc Type Geared Coupling. Shear pin type Geared Coupling.

Shear pin type Geared Coupling. Slide type Geared Coupling.

Slide type Geared Coupling. Vertical type Geared Coupling.

Vertical type Geared Coupling. Single sleeve type Geared Coupling.

Single sleeve type Geared Coupling. Floating Shaft type Geared Coupling.

Floating Shaft type Geared Coupling. Limiting end-float geared Coupling.

Limiting end-float geared Coupling. Torsion Shaft Geared Coupling.

Torsion Shaft Geared Coupling.